We All Scream for Screen Printing

Fieldtrip!

The Grapevine Designs Design Team visited a local screen printing operation to get an up-close-and- personal look at the screen printing process. We wanted to see the magic that turns Grapevine’s digital files into a perfectly finished product.

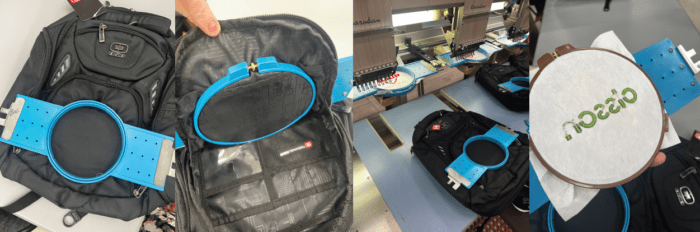

We arrived at 9:30 am on a blistering Tuesday. Once we all arrived in the same place (what gives, Siri?), the excitement was palpable. The co-owner and a guy with a big screen-printing brain, met us in the lobby and introduced us to staff. Then we proceeded to the action. First stop, embroidery. This was an unexpected stop on our tour and a very cool surprise. News flash! Embroidery is not what it used to be. I expected to walk into a roomful of grandmas in rocking chairs, stitching away and trading recipes and gossip. As much as I wanted this to be true (and to join them in the gossip), I might have been romanticizing the operation. Embroidery is high-tech and fast. The company has a slew of embroidery machines that can stitch 5,000 stitches in 7 minutes! (That’s a production of 30 pieces in an hour!) I mean, Grandma was fast, but…

Here’s a few other amazing embroidery facts:

- The number of stitches determines the time on the machine.

- The machines stitch from the inside out and operate off digital files set up by the designers.

- The machines cannot stitch under a ¼” or over 2 ½” in height for text. (there goes my idea for a hat that says LOOK AT MY CAT in 5” lettering.)

Despite all this technology, there are a few throwbacks in the process. Hoops, not unlike the ones used in embroidery, are used to prevent the machine from stitching through the bottom layer. And traditional sewing machines are still used for patches on hats and hem tags.

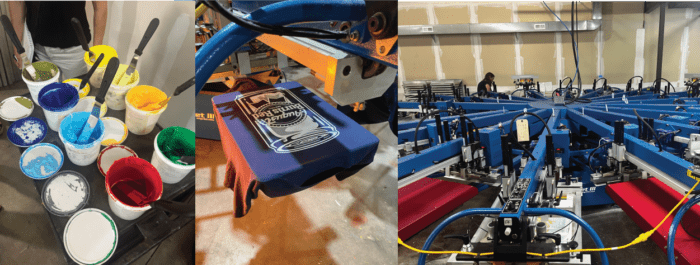

Next…screen printing. The main event. What is screen printing? As a copywriter who is two years new to the world of promotional marketing, I have heard the term screen-printing thrown around a lot. But, even after seeing the process, I had to read about it. Because, WORDS MATTER.

Screen printing is the process of transferring a stenciled design onto a flat surface using a screen, ink or paint, and squeegee. In this case, it’s a machine that pushes the ink through a screen to create an imprint of the design on the surface beneath. Designs can be made using one color or using multiple colors which involves separate screens for each individual color. Speaking of colors, this screen printing operation can print up to 12 colors (more than any other screen printing operation in Kansas City). This enables them to print the PRIDE logo, for example.

Some other facts about screen printing:

- The process is popular because it can produce vivid color in large areas

- Colors used in screen-printing are mixed on-site to match Pantone colors (but black is the easiest color to print)

- Screen burning is the process by which a design is “burned” onto a screen with a UV light

- Screens are like plates at a restaurant, once they’re used, they’re used again and go through a post-use cleaning process

Our field trip concluded with Grapevine’s Design team meeting with the in-house design team to discuss setting up file enhancements to make the process more seamless, ensuring we deliver the highest quality product to our clients. Screen printing is a complicated process but the great team members that we met on our field trip are experts.

They employ their endless knowledge, passion for perfection, and problem-solving prowess to figure out how to get the job done. And their results are undeniable.